Page 180 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 180

160 SILICON MICROMACHINING: SURFACE

Shield Bushing Bearing Rotor Stator

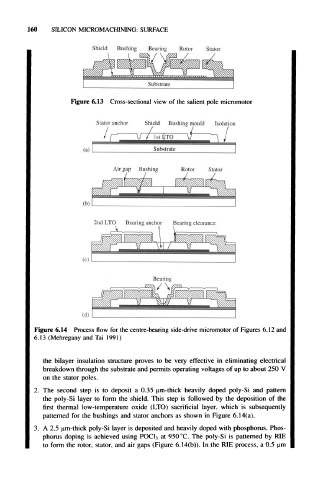

Figure 6.13 Cross-sectional view of the salient pole micromotor

/,— U / / IstI TO V? / ^ / /

Stator anchor Shield Bushing mould Isolation

(a) Substrate

Air gap Bushing Rotor Stator

2nd LTO Bearing anchor Bearing clearance

Figure 6.14 Process flow for the centre-bearing side-drive micromotor of Figures 6.12 and

6.13 (Mehregany and Tai 1991)

the bilayer insulation structure proves to be very effective in eliminating electrical

breakdown through the substrate and permits operating voltages of up to about 250 V

on the stator poles.

2. The second step is to deposit a 0.35 um-thick heavily doped poly-Si and pattern

the poly-Si layer to form the shield. This step is followed by the deposition of the

first thermal low-temperature oxide (LTO) sacrificial layer, which is subsequently

patterned for the bushings and stator anchors as shown in Figure 6.14(a).

3. A 2.5 um-thick poly-Si layer is deposited and heavily doped with phosphorus. Phos-

phorus doping is achieved using POC1 3 at 950 °C. The poly-Si is patterned by RIE

to form the rotor, stator, and air gaps (Figure 6.14(b)). In the RIE process, a 0.5 (am