Page 175 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 175

MATERIAL SYSTEMS IN SACRIFICIAL LAYER TECHNOLOGY 155

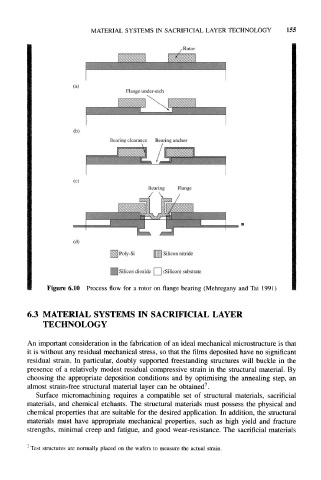

Rotor

(a)

Flange under-etch

Bearing clearance Bearing anchor

Bearing Flange

(d)

H Poly-Si _ Silicon nitride

Silicon dioxide | | (Silicon) substrate

Figure 6.10 Process flow for a rotor on flange bearing (Mehregany and Tai 1991)

6.3 MATERIAL SYSTEMS IN SACRIFICIAL LAYER

TECHNOLOGY

An important consideration in the fabrication of an ideal mechanical microstructure is that

it is without any residual mechanical stress, so that the films deposited have no significant

residual strain. In particular, doubly supported freestanding structures will buckle in the

presence of a relatively modest residual compressive strain in the structural material. By

choosing the appropriate deposition conditions and by optimising the annealing step, an

7

almost strain-free structural material layer can be obtained .

Surface micromachining requires a compatible set of structural materials, sacrificial

materials, and chemical etchants. The structural materials must possess the physical and

chemical properties that are suitable for the desired application. In addition, the structural

materials must have appropriate mechanical properties, such as high yield and fracture

strengths, minimal creep and fatigue, and good wear-resistance. The sacrificial materials

' Test structures are normally placed on the wafers to measure the actual strain.