Page 33 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 33

PATTERN TRANSFER 15

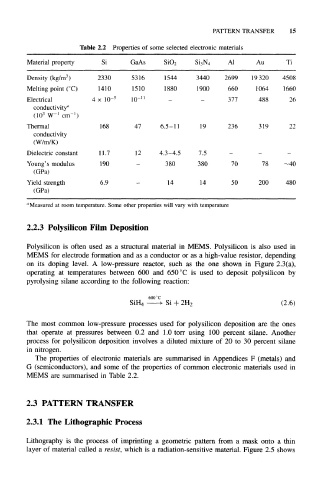

Table 2.2 Properties of some selected electronic materials

Material property Si GaAs SiO 2 Si 3N 4 Al Au Ti

3

Density (kg/m ) 2330 5316 1544 3440 2699 19320 4508

Melting point (°C) 1410 1510 1880 1900 660 1064 1660

Electrical 4 x 10 -5 10 -11 - - 377 488 26

conductivity"

-1

-1

(10 3 W cm )

Thermal 168 47 6.5-11 19 236 319 22

conductivity

(W/m/K)

Dielectric constant 11.7 12 4.3-4.5 7.5 - - -

Young's modulus 190 - 380 380 70 78 -40

(GPa)

Yield strength 6.9 — 14 14 50 200 480

(GPa)

"Measured at room temperature. Some other properties will vary with temperature

2.2.3 Polysilicon Film Deposition

Polysilicon is often used as a structural material in MEMS. Polysilicon is also used in

MEMS for electrode formation and as a conductor or as a high-value resistor, depending

on its doping level. A low-pressure reactor, such as the one shown in Figure 2.3(a),

operating at temperatures between 600 and 650 °C is used to deposit poly silicon by

pyrolysing silane according to the following reaction:

600°C

(2.6)

SiH 4 Si + 2H 2

The most common low-pressure processes used for polysilicon deposition are the ones

that operate at pressures between 0.2 and 1.0 torr using 100 percent silane. Another

process for polysilicon deposition involves a diluted mixture of 20 to 30 percent silane

in nitrogen.

The properties of electronic materials are summarised in Appendices F (metals) and

G (semiconductors), and some of the properties of common electronic materials used in

MEMS are summarised in Table 2.2.

2.3 PATTERN TRANSFER

2.3.1 The Lithographic Process

Lithography is the process of imprinting a geometric pattern from a mask onto a thin

layer of material called a resist, which is a radiation-sensitive material. Figure 2.5 shows