Page 438 - Orlicky's Material Requirements Planning

P. 438

416 PART 4 Looking Backward and Forward

(rebuild zone) will be penetrated more frequently. This means that there will be a steady

stream of open supply orders. This extends a larger percentage of the buffer position to

inbound supply. Having more open supply orders also means that the red zone base can

be minimized. The presence of a significant MOQ often will block or challenge this green

zone strategy owing to the inherent lumpiness caused by the MOQ.

Two steps are necessary to determine if an MOQ is significant. First, the part’s green

zone is calculated based on the lead-time category it falls in without consideration of

MOQ. Second, a comparison must be made of the calculated green zone quantity and that

MOQ. If the order minimum is greater than the size of the calculated green zone, then the

MOQ is significant. The green zone then is sized to the MOQ.

For example, Part XYZ has an ADU of 6 and a lead time of 20 days. It is coded a

long-lead-time part, in which its green zone will be 30 percent of usage over lead time (36

units). If this part has an MOQ of 48 units, this would qualify as a significant MOQ (48

36). This designation means that the buffer profile of this part will be changed to an MOQ

profile. Under MOQ profiles, the green zone is set to the MOQ (48 units). In this exam-

ple, the MOQ equals 8 days of average daily usage [48 units (MOQ)/6 units (ADU) 8

days]. Eight days, incidentally, means that the green zone will end up being sized at 40

percent of usage over lead time.

Variability Category Buffer Impact

The variability category will size the red zone safety portion of the total red zone. Early

in development of this solution, the thinking was that red zone safety might best be

described as a factor of ADU (e.g., 2 ADU, 3 ADU, etc.). This quickly creates a prob-

lem for the variability factor to be managed effectively at a global level. Within a buffer

profile there still can be relatively wide discrepancies between the discrete lead times of

parts, especially long-lead-time parts. The same issue applies to expressing red zone safe-

ty as a percentage of usage over lead time. The most effective heuristic is that red zone

safety should be an expression of a percentage of the red zone base. By doing this, there

is a smoothing effect that happens between parts that have lead-time disparities within

the same buffer profile.

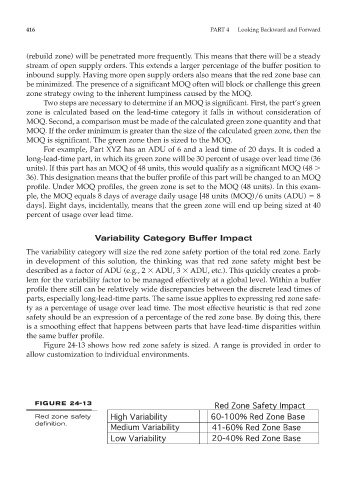

Figure 24-13 shows how red zone safety is sized. A range is provided in order to

allow customization to individual environments.

FIGURE 24-13

Red zone safety

definition.