Page 317 - Power Electronics Handbook

P. 317

Inverter circuits 307

13.2.4.2 Commutation loss reduction

Commutation losses can be reduced, as was done for choppers, by several

techniques. For example, Figure 13.1 l(b) illustrated a popular push-pull

parallel commutated inverter configuration, which is not suitable for

high-frequency operation due to its large commutation loss. When TH1

fires, capacitor C discharges through inductor L1 and recharges to twice the

supply voltage. When this has been completed diode D1 conducts, feeding

back the inductive load current to the supply, and the energy stored in L1

during the commutation interval is dissipated in the loop L1-D1-TH1.

Load

D2

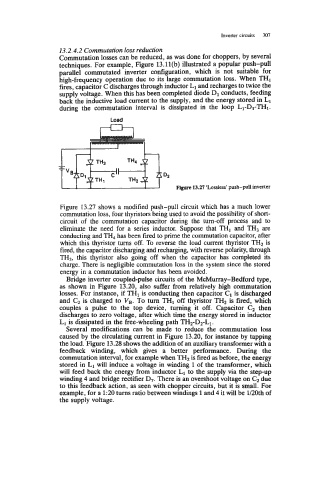

Figure 13.27 ‘Lossless’ push-pull inverter

Figure 13.27 shows a modified push-pull circuit which has a much lower

commutation loss, four thyristors being used to avoid the possibility of short-

circuit of the commutation capacitor during the turn-off process and to

eliminate the need for a series inductor. Suppose that TH, and TH3 are

conducting and TH, has been fired to prime the commutation capacitor, after

which this thyristor turns off. To reverse the load current thyristor TH, is

fired, the capacitor discharging and recharging, with reverse polarity, through

TH3, this thyristor also going off when the capacitor has completed its

charge. There is negligible commutation loss in the system since the stored

energy in a commutation inductor has been avoided.

Bridge inverter coupled-pulse circuits of the McMurray-Bedford typ,

as shown in Figure 13.20, also suffer from relatively high commutation

losses. For instance, if TH1 is conducting then capacitor C1 is discharged

and C, is charged to VB. To turn TH1 off thyristor TH2 is fired, which

couples a pulse to the top device, turning it off. Capacitor C, then

discharges to zero voltage, after which time the energy stored in inductor

L1 is dissipated in the free-wheeling path TH2-D2-L1.

Several modifications can be made to reduce the commutation loss

caused by the circulating current in Figure 13.20, for instance by tapping

the load. Figure 13.28 shows the addition of an auxiliary transformer with a

feedback winding, which gives a better performance. During the

commutation interval, for example when THz is fired as before, the energy

stored in L1 will induce a voltage in winding 1 of the transformer, which

will feed back the energy from inductor L1 to the supply via the step-up

winding 4 and bridge rectifier D7. There is an overshoot voltage on due

to this feedback action, as seen with chopper circuits, but it is small. For

example, for a 1:20 turns ratio between windings 1 and 4 it will be 1/20th of

the supply voltage.