Page 195 - Semiconductor Manufacturing Handbook

P. 195

Geng(SMH)_CH13.qxd 04/04/2005 19:51 Page 13.18

PHYSICAL VAPOR DEPOSITION

13.18 WAFER PROCESSING

HF/RF HF/RF

power matching

supply network Pre-vacuum/

Base plate

Cooling water loading chamber

Shield Target Conveyor transport

system

Aperture

Residual gas

analyzer

Gas inlet

Palette Cooling

water

Vacuum pumps Load lock Load lock

Substrates

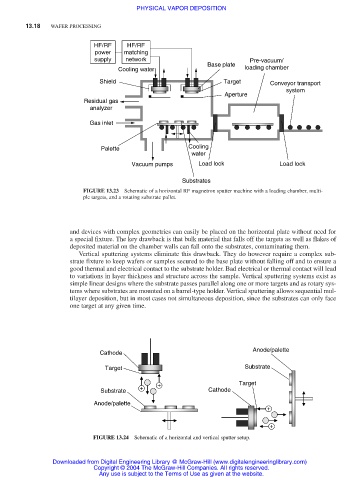

FIGURE 13.23 Schematic of a horizontal RF magnetron sputter machine with a loading chamber, multi-

ple targets, and a rotating substrate pallet.

and devices with complex geometries can easily be placed on the horizontal plate without need for

a special fixture. The key drawback is that bulk material that falls off the targets as well as flakes of

deposited material on the chamber walls can fall onto the substrates, contaminating them.

Vertical sputtering systems eliminate this drawback. They do however require a complex sub-

strate fixture to keep wafers or samples secured to the base plate without falling off and to ensure a

good thermal and electrical contact to the substrate holder. Bad electrical or thermal contact will lead

to variations in layer thickness and structure across the sample. Vertical sputtering systems exist as

simple linear designs where the substrate passes parallel along one or more targets and as rotary sys-

tems where substrates are mounted on a barrel-type holder. Vertical sputtering allows sequential mul-

tilayer deposition, but in most cases not simultaneous deposition, since the substrates can only face

one target at any given time.

Anode/palette

Cathode

Target Substrate

+ Target

+

Substrate Cathode

Anode/palette

+ +

+ +

FIGURE 13.24 Schematic of a horizontal and vertical sputter setup.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.