Page 510 - Shigley's Mechanical Engineering Design

P. 510

bud29281_ch09_475-516.qxd 12/24/2009 1:46 pm Page 485 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

Welding, Bonding, and the Design of Permanent Joints 485

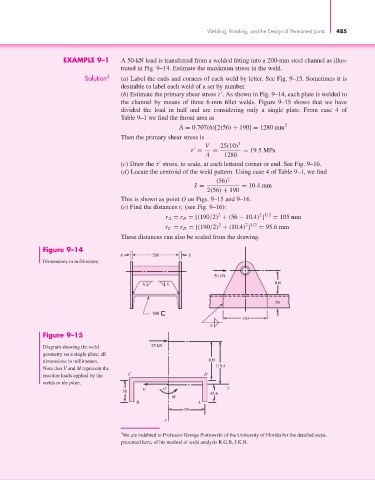

EXAMPLE 9–1 A 50-kN load is transferred from a welded fitting into a 200-mm steel channel as illus-

trated in Fig. 9–14. Estimate the maximum stress in the weld.

Solution 3 (a) Label the ends and corners of each weld by letter. See Fig. 9–15. Sometimes it is

desirable to label each weld of a set by number.

(b) Estimate the primary shear stress τ . As shown in Fig. 9–14, each plate is welded to

the channel by means of three 6-mm fillet welds. Figure 9–15 shows that we have

divided the load in half and are considering only a single plate. From case 4 of

Table 9–1 we find the throat area as

A = 0.707(6)[2(56) + 190] = 1280 mm 2

Then the primary shear stress is

V 25(10) 3

τ = = = 19.5MPa

A 1280

(c) Draw the τ stress, to scale, at each lettered corner or end. See Fig. 9–16.

(d) Locate the centroid of the weld pattern. Using case 4 of Table 9–1, we find

(56) 2

¯ x = = 10.4mm

2(56) + 190

This is shown as point O on Figs. 9–15 and 9–16.

(e) Find the distances r i (see Fig. 9–16):

2

2 1/2

r A = r B = [(190/2) + (56 − 10.4) ] = 105 mm

2 1/2

2

r C = r D = [(190/2) + (10.4) ] = 95.6mm

These distances can also be scaled from the drawing.

Figure 9–14

6 200 6

Dimensions in millimeters.

50 kN

6 6 100

56

200

190

6

Figure 9–15

Diagram showing the weld 25 kN

geometry on a single plate; all

dimensions in millimeters. 100

110.4

Note that V and M represent the

reaction loads applied by the C D

welds to the plate.

V O y

56

45.6

M

B A

95

x

3 We are indebted to Professor George Piotrowski of the University of Florida for the detailed steps,

presented here, of his method of weld analysis R.G.B, J.K.N.