Page 223 - Statistics for Environmental Engineers

P. 223

L1592_frame_C25.fm Page 225 Tuesday, December 18, 2001 2:45 PM

binders (e.g., phenol formaldehyde, phenol isocyanate, alkyl isocyanate). The typical solid waste of a

foundry is two thirds or more system sand, 2 to 20% core sand and core butts, and up to 11% dust collected

in the baghouse that is used for air pollution control.

These wastes are generally put into landfills. Most of the waste is inert (sand) but certain compo-

nents have the potential of being leached from the landfill and entering subsurface soils and ground-

water. Studies of leachate from foundry landfills have shown large variations in chemical composition.

The variation may arise from the nonuniformity of the waste materials deposited in the landfill, but it

also may have other causes. This raises questions about how large a sample should be collected in the

field, and whether this sample should be a composite of many small portions. There are also questions

about how to partition a large field specimen into smaller portions that are suitable for laboratory analysis.

Finally, the laboratory work itself cannot be overlooked as a possible source of variability.

These considerations point to the need for replicate specimens and replicate measurements. An efficient

protocol for sampling and analytical replication cannot be designed until the sources of variation are

identified and quantified. The major source of variation might be between field specimens, from sub-

specimens prepared in the laboratory, or from the analytical procedure itself.

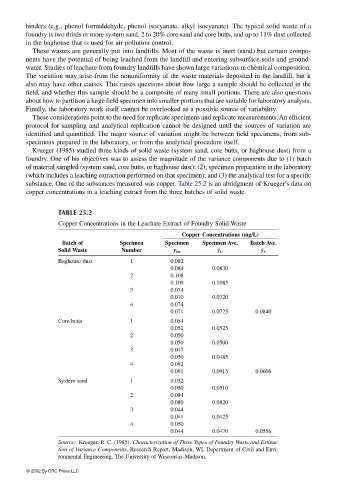

Krueger (1985) studied three kinds of solid waste (system sand, core butts, or baghouse dust) from a

foundry. One of his objectives was to assess the magnitude of the variance components due to (1) batch

of material sampled (system sand, core butts, or baghouse dust); (2); specimen preparation in the laboratory

(which includes a leaching extraction performed on that specimen); and (3) the analytical test for a specific

substance. One of the substances measured was copper. Table 25.2 is an abridgment of Krueger’s data on

copper concentrations in a leaching extract from the three batches of solid waste.

TABLE 25.2

Copper Concentrations in the Leachate Extract of Foundry Solid Waste

Copper Concentrations (mg// //L)

Batch of Specimen Specimen Specimen Ave. Batch Ave.

Solid Waste Number y bst y bs y b

Baghouse dust 1 0.082

0.084 0.0830

2 0.108

0.109 0.1085

3 0.074

0.070 0.0720

4 0.074

0.071 0.0725 0.0840

Core butts 1 0.054

0.051 0.0525

2 0.050

0.050 0.0500

3 0.047

0.050 0.0485

4 0.092

0.091 0.0915 0.0606

System sand 1 0.052

0.050 0.0510

2 0.084

0.080 0.0820

3 0.044

0.041 0.0425

4 0.050

0.044 0.0470 0.0556

Source: Krueger, R. C. (1985). Characterization of Three Types of Foundry Waste and Estima-

tion of Variance Components, Research Report, Madison, WI, Department of Civil and Envi-

ronmental Engineering, The University of Wisconsin–Madison.

© 2002 By CRC Press LLC