Page 210 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 210

196 P r o c e s s C o n t r o l Q u a n t i f y i n g P r o c e s s Va r i a t i o n 197

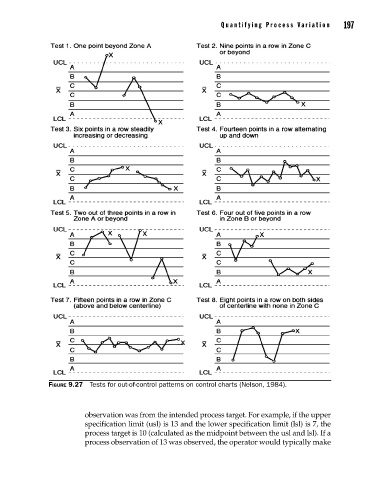

Figure 9.27 Tests for out-of-control patterns on control charts (Nelson, 1984).

observation was from the intended process target. For example, if the upper

specification limit (usl) is 13 and the lower specification limit (lsl) is 7, the

process target is 10 (calculated as the midpoint between the usl and lsl). If a

process observation of 13 was observed, the operator would typically make

09_Pyzdek_Ch09_p151-208.indd 197 11/21/12 1:42 AM