Page 223 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 223

Engineering Design with SOLIDWORKS® 2018 Fundamentals of Assembly Modeling

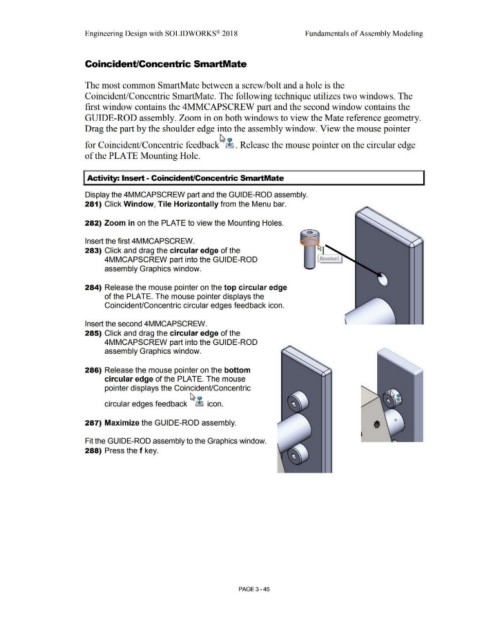

Coincident/Concentric SmartMate

The most common SmartMate between a screw/bolt and a hole is the

Coincident/Concentric SmartMate. The following technique utilizes two windows. The

first window contains the 4MMCAPSCREW part and the second window contains the

GUIDE-ROD assembly. Zoom in on both windows to view the Mate reference geometry.

Drag the part by the shoulder edge into the assembly window. View the mouse pointer

for Coincident/Concentric feedback ~&i. Release the mouse pointer on the circular edge

of the PLATE Mounting Hole.

Activity: Insert - Coincident/Concentric SmartMate

Display the 4MMCAPSCREW part and the GUIDE-ROD assembly.

281) Click Window, Tile Horizontally from the Menu bar.

282) Zoom in on the PLATE to view the Mounting Holes.

Insert the first 4MMCAPSCREW.

283) Click and drag the circular edge of the

4MMCAPSCREW part into the GUIDE-ROD Revolve!

assembly Graphics window.

284) Release the mouse pointer on the top circular edge

of the PLATE. The mouse pointer displays the

Coincident/Concentric circular edges feedback icon.

Insert the second 4MMCAPSCREW.

285) Click and drag the circular edge of the

4MMCAPSCREW part into the GUIDE-ROD

assembly Graphics window.

286) Release the mouse pointer on the bottom

circular edge of the PLATE. The mouse

pointer displays the Coincident/Concentric

~ ~

circular edges feedback ~ icon.

287) Maximize the GUIDE-ROD assembly.

Fit the GUIDE-ROD assembly to the Graphics window.

288) Press the f key.

PAGE 3-45