Page 228 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 228

Fundamentals of Assembly Modeling Engineering Design with SOLIDWORKS® 2018

, 1 /

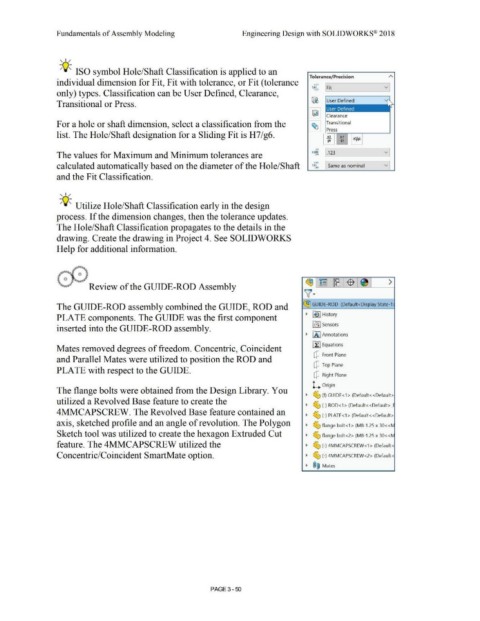

-;Q~ ISO symbol Hole/Shaft Classification is applied to an

Tolerance/Precision

individual dimension for Fit, Fit with tolerance, or Fit (tolerance 1

,.;0° rFit v

- . 0 1

only) types. Classification can be User Defined, Clearance,

Transitional or Press.

Clearance

For a hole or shaft dimension, select a classification from the Transitional

Press

list. The Hole/Shaft designation for a Sliding Fit is H7 /g6. .fil.

96 HJ H7'-6

96

1~

.01 I v

.123

x.xxx

The values for Maximum and Minimum tolerances are .01 ~------

+.xx I

calculated automatically based on the diameter of the Hole/Shaft ,.~~. Same as nominal v

and the Fit Classification.

, 1 /

-;Q~ Utilize Hole/Shaft Classification early in the design

process. If the dimension changes, then the tolerance updates.

The Hole/Shaft Classification propagates to the details in the

drawing. Create the drawing in Project 4. See SOLIDWORKS

Help for additional information.

>

Review of the GUIDE-ROD Assembly

The GUIDE-ROD assembly combined the GUIDE, ROD and ~ GUIDE-ROD (Default<Display State-1.

PLATE components. The GUIDE was the first component • ~ I History

ifiJ Sensors

inserted into the GUIDE-ROD assembly.

• fA I Annotations

~ Equations

Mates removed degrees of freedom. Concentric, Coincident

[? Front Plane

and Parallel Mates were utilized to position the ROD and

[? Top Plane

PLATE with respect to the GUIDE.

[? Right Plane

L Origin

The flange bolts were obtained from the Design Library. You

• ~ (f) GUIDE<1 > (Default<<Default>

utilized a Revolved Base feature to create the

• ~ (-) ROD<1> (Default<<Default>_I

4MMCAPSCREW. The Revolved Base feature contained an

• ~ (-) PLATE<1 > (Default< <Default>

axis, sketched profile and an angle of revolution. The Polygon • ~ flange bolt<1> (M8-1.25 x 30<<N

Sketch tool was utilized to create the hexagon Extruded Cut • ~ flange bolt<2> (M8-1.25 x 30<<N

feature. The 4MMCAPSCREW utilized the • ~ (-) 4MMCAPSCREW<1> (Default<

Concentric/Coincident SmartMate option. • ~ (-) 4MMCAPSCREW<2> (Default<

• ®@ Mates

PAGE 3 - 50