Page 494 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 494

Swept, Lofted and Additional Features Engineering Design with SOLIDWORKS® 2018

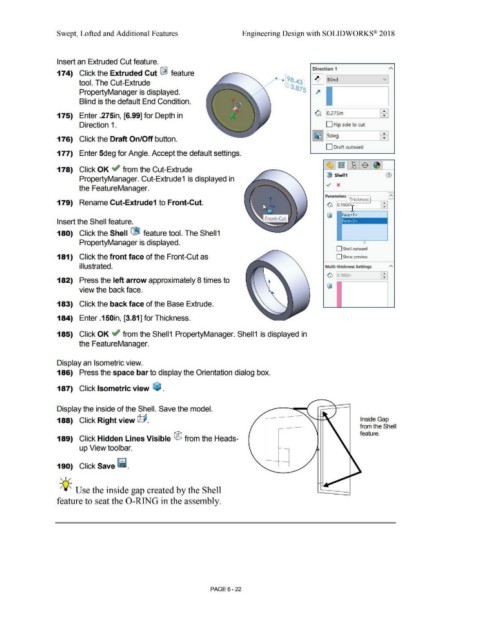

Insert an Extruded Cut feature.

Direction 1

174) Click the Extruded Cut [&! feature

~ .__:s,_ind ____ __.v I

tool. The Cut-Extrude

PropertyManager is displayed. 74

Blind is the default End Condition.

175) Enter .275in, [6.99] for Depth in ~ [o.27Sin [:]

Direction 1 . D Flip side to cut

176) Click the Draft On/Off button. ~ jL--sde_g ----------=ffi===": I

D Draft outward

177) Enter 5deg for Angle. Accept the default settings.

~·~ ltcB l$ l~I

178) Click OK .; from the Cut-Extrude

(l!9 Shell 1 (1)

PropertyManager. Cut-Extrude1 is displayed in

v x

the FeatureManager.

Parameters I h. k l I Aj

. T 1c ness .

179) Rename Cut-Extrude1 to Front-Cut. G o.,soi k:

Insert the Shell feature.

180) Click the Shell ['.j9 feature tool. The Shell1

PropertyManager is displayed. t)

D Shell outward

181) Click the front face of the Front-Cut as D Show preview

illustrated. Multi-thickness Settings A

G lo.1ooin Ff

182) Press the left arrow approximately 8 times to

~

view the back face.

183) Click the back face of the Base Extrude.

184) Enter .150in, [3.81] for Thickness.

185) Click OK .; from the Shell 1 PropertyManager. Shell 1 is displayed in

the FeatureManager.

Display an Isometric view.

186) Press the space bar to display the Orientation dialog box.

187) Click Isometric view ~ .

Display the inside of the Shell. Save the model.

188) Click Right view @. Inside Gap

from the Shell

feature.

189) Click Hidden Lines Visible ® from the Heads-

up View toolbar.

190) Click Save ii.

, ,/

-;Q;_ Use the inside gap created by the Shell

feature to seat the 0-RING in the assembly.

PAGE6 - 22