Page 328 - Fundamentals of Gas Shale Reservoirs

P. 328

308 RESOURCE ESTIMATION FOR SHALE GAS RESERVOIRS

History Projection

35

30

U.S. Gas Consumption (Tcf ) 20 32% Net import

25

8%

Shale gas

15

23%

Tight gas

10

5 8% Coalbed methane

29% Conventional gas

0

1990 1995 2000 2005 2010 2015 2020 2025 2030 2035 2040

Year

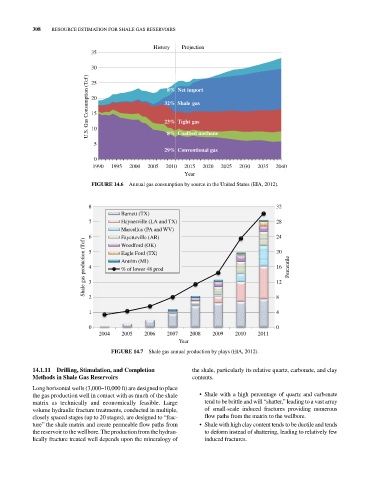

FIGURE 14.6 Annual gas consumption by source in the United States (EIA, 2012).

8 32

arnett (TX

B

Barnett (TX) )

Haynesville (LA and TX)

7 Haynesville (LA and TX) 28

Marcellus (PA and WV)

Marcellus (PA and WV)

6 5 Fayetteville (AR) 24

Fayetteville (AR)

Shale gas production (Tcf) 4 3 Eagle Ford (TX) 16 Percentile

Woodford (OK)

Woodford (OK)

20

Eagle Ford (TX)

Antrim (MI)

Antrim (MI)

% of lower 48 prod

% of lower 48 prod

12

1 2 8

4

0 0

2004 2005 2006 2007 2008 2009 2010 2011

Year

FIGURE 14.7 Shale gas annual production by plays (EIA, 2012).

14.1.11 Drilling, Stimulation, and Completion the shale, particularly its relative quartz, carbonate, and clay

Methods in Shale Gas Reservoirs contents.

Long horizontal wells (3,000–10,000 ft) are designed to place

the gas production well in contact with as much of the shale • Shale with a high percentage of quartz and carbonate

matrix as technically and economically feasible. Large tend to be brittle and will “shatter,” leading to a vast array

volume hydraulic fracture treatments, conducted in multiple, of small‐scale induced fractures providing numerous

closely spaced stages (up to 20 stages), are designed to “frac- flow paths from the matrix to the wellbore.

ture” the shale matrix and create permeable flow paths from • Shale with high clay content tends to be ductile and tends

the reservoir to the wellbore. The production from the hydrau- to deform instead of shattering, leading to relatively few

lically fracture treated well depends upon the mineralogy of induced fractures.