Page 410 - High Power Laser Handbook

P. 410

378 So l i d - S t at e La s e r s The National Ignition Facility Laser 379

o

c

E

e 2ω

E 3ω

E 1ω

e

c

Type II THG

+ k = k

k 1e 2o 3e

dKDP

E 1ω o

Type I SHG

+ k = k

k 1o 1o 2e

KDP

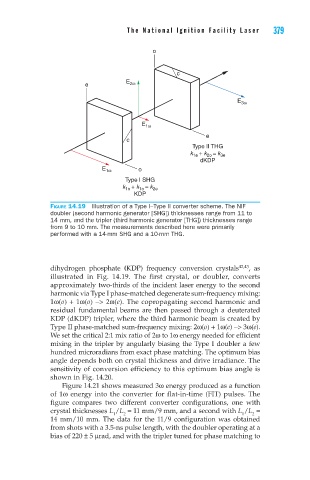

Figure 14.19 Illustration of a Type I–Type II converter scheme. The NIF

doubler (second harmonic generator [SHG]) thicknesses range from 11 to

14 mm, and the tripler (third harmonic generator [THG]) thicknesses range

from 9 to 10 mm. The measurements described here were primarily

performed with a 14-mm SHG and a 10-mm THG.

dihydrogen phosphate (KDP) frequency conversion crystals 42,43 , as

illustrated in Fig. 14.19. The first crystal, or doubler, converts

approximately two-thirds of the incident laser energy to the second

harmonic via Type I phase-matched degenerate sum-frequency mixing:

1ω(o) + 1ω(o) −> 2ω(e). The copropagating second harmonic and

residual fundamental beams are then passed through a deuterated

KDP (dKDP) tripler, where the third harmonic beam is created by

Type II phase-matched sum-frequency mixing: 2ω(o) + 1ω(e) −> 3ω(e).

We set the critical 2:1 mix ratio of 2ω to 1ω energy needed for efficient

mixing in the tripler by angularly biasing the Type I doubler a few

hundred microradians from exact phase matching. The optimum bias

angle depends both on crystal thickness and drive irradiance. The

sensitivity of conversion efficiency to this optimum bias angle is

shown in Fig. 14.20.

Figure 14.21 shows measured 3ω energy produced as a function

of 1ω energy into the converter for flat-in-time (FIT) pulses. The

figure compares two different converter configurations, one with

crystal thicknesses L /L = 11 mm/9 mm, and a second with L /L =

2

1

2

1

14 mm/10 mm. The data for the 11/9 configuration was obtained

from shots with a 3.5-ns pulse length, with the doubler operating at a

bias of 220 ± 5 μrad, and with the tripler tuned for phase matching to