Page 454 - Industrial Power Engineering and Applications Handbook

P. 454

14/428 Industrial Power Engineering and Applications Handbook

Remove the links and

Main short the vertical View-A

busbars bus separately I

Shorting

/ links

Main busbars Shorting links

-1 of this row) x (diversity factor).

w

View-A

Vertical sectional bus 200A

[(sum of all the vertical feeders

But considered as min 200Al

c

\

Variable current injection \-v-' ' - ; : \ Variable current injection

set for the main bus Dummy panel Panel under test Dummy panel set for the vertical bus

0-2000 A, 3-10 V 0-IOOOA, 3-10 V

Note: Dummy panels are also heated simultaneously, Location of RTD'S

the same way, as the panel under test

0 Location of heaters

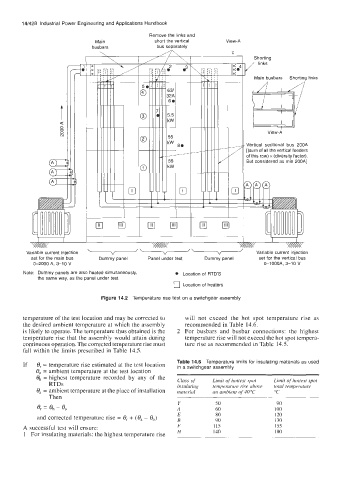

Figure 14.2 Temperature rise test on a switchgear assembly

temperature of the test location and may be corrected to will not exceed the hot spot temperature rise as

the desired ambient temperature at which the assembly recommended in Table 14.6.

is likely to operate. The temperature thus obtained is the 2 For busbars and busbar connections: the highest

temperature rise that the assembly would attain during temperature rise will not exceed the hot spot tempera-

continuous operation. The corrected temperature rise must ture rise as recommended in Table 14.5.

fall within the limits prescribed in Table 14.5.

If 8, = temperature rise estimated at the test location Table 14.6 Temperature limits for insulating materials as used

in a switchgear assembly

0, = ambient temperature at the test location

O,, = highest temperature recorded by any of the

RTDs Class f3f Limit of hottest spot Limit of hottest spot

temperature rise ubove

8, = ambient temperature at the place of installation insuluting an ambient of 40 "C total temperuture

materiul

"C

Then

Y 50 90

8, = O,, - 8, A 60 100

and corrected temperature rise = 8, + (8, - 8,) E 80 120

B 90 130

A successful test will ensure: F I15 155

1 For insulating materials: the highest temperature rise H 140 180