Page 137 - System on Package_ Miniaturization of the Entire System

P. 137

112 Cha pte r T h ree

TAB Stacking

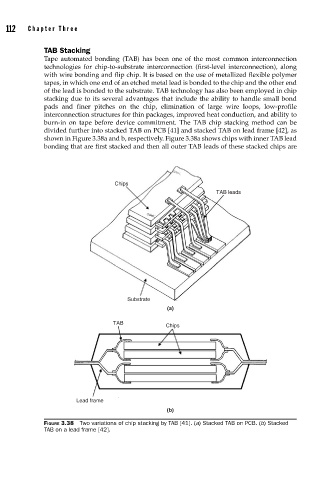

Tape automated bonding (TAB) has been one of the most common interconnection

technologies for chip-to-substrate interconnection (first-level interconnection), along

with wire bonding and flip chip. It is based on the use of metallized flexible polymer

tapes, in which one end of an etched metal lead is bonded to the chip and the other end

of the lead is bonded to the substrate. TAB technology has also been employed in chip

stacking due to its several advantages that include the ability to handle small bond

pads and finer pitches on the chip, elimination of large wire loops, low-profile

interconnection structures for thin packages, improved heat conduction, and ability to

burn-in on tape before device commitment. The TAB chip stacking method can be

divided further into stacked TAB on PCB [41] and stacked TAB on lead frame [42], as

shown in Figure 3.38a and b, respectively. Figure 3.38a shows chips with inner TAB lead

bonding that are first stacked and then all outer TAB leads of these stacked chips are

Chips

TAB leads

Substrate

(a)

TAB

Chips

Lead frame

(b)

FIGURE 3.38 Two variations of chip stacking by TAB [41]. (a) Stacked TAB on PCB. (b) Stacked

TAB on a lead frame [42].