Page 143 - System on Package_ Miniaturization of the Entire System

P. 143

118 Cha pte r T h ree

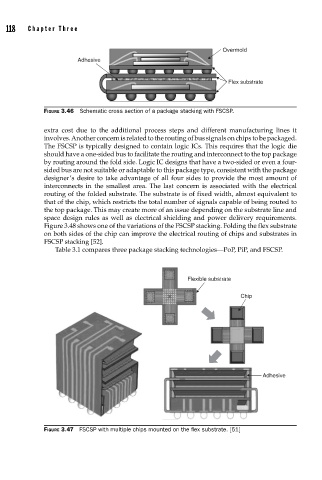

Overmold

Adhesive

Flex substrate

FIGURE 3.46 Schematic cross section of a package stacking with FSCSP.

extra cost due to the additional process steps and different manufacturing lines it

involves. Another concern is related to the routing of bus signals on chips to be packaged.

The FSCSP is typically designed to contain logic ICs. This requires that the logic die

should have a one-sided bus to facilitate the routing and interconnect to the top package

by routing around the fold side. Logic IC designs that have a two-sided or even a four-

sided bus are not suitable or adaptable to this package type, consistent with the package

designer’s desire to take advantage of all four sides to provide the most amount of

interconnects in the smallest area. The last concern is associated with the electrical

routing of the folded substrate. The substrate is of fixed width, almost equivalent to

that of the chip, which restricts the total number of signals capable of being routed to

the top package. This may create more of an issue depending on the substrate line and

space design rules as well as electrical shielding and power delivery requirements.

Figure 3.48 shows one of the variations of the FSCSP stacking. Folding the flex substrate

on both sides of the chip can improve the electrical routing of chips and substrates in

FSCSP stacking [52].

Table 3.1 compares three package stacking technologies—PoP, PiP, and FSCSP.

Flexible substrate

Chip

Adhesive

FIGURE 3.47 FSCSP with multiple chips mounted on the fl ex substrate. [51]