Page 144 - System on Package_ Miniaturization of the Entire System

P. 144

Stacked ICs and Packages (SIP) 119

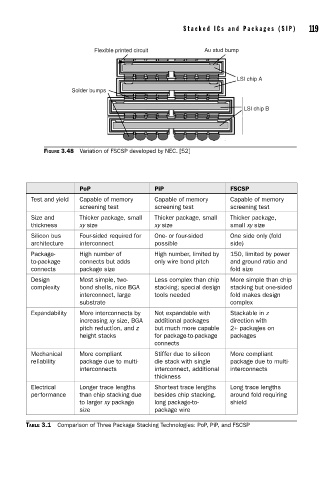

Flexible printed circuit Au stud bump

LSI chip A

Solder bumps

LSI chip B

FIGURE 3.48 Variation of FSCSP developed by NEC. [52]

PoP PiP FSCSP

Test and yield Capable of memory Capable of memory Capable of memory

screening test screening test screening test

Size and Thicker package, small Thicker package, small Thicker package,

thickness xy size xy size small xy size

Silicon bus Four-sided required for One- or four-sided One side only (fold

architecture interconnect possible side)

Package- High number of High number, limited by 150, limited by power

to-package connects but adds only wire bond pitch and ground ratio and

connects package size fold size

Design Most simple, two- Less complex than chip More simple than chip

complexity bond shells, nice BGA stacking; special design stacking but one-sided

interconnect, large tools needed fold makes design

substrate complex

Expandability More interconnects by Not expandable with Stackable in z

increasing xy size, BGA additional packages direction with

pitch reduction, and z but much more capable 2+ packages on

height stacks for package-to-package packages

connects

Mechanical More compliant Stiffer due to silicon More compliant

reliability package due to multi- die stack with single package due to multi-

interconnects interconnect, additional interconnects

thickness

Electrical Longer trace lengths Shortest trace lengths Long trace lengths

performance than chip stacking due besides chip stacking, around fold requiring

to larger xy package long package-to- shield

size package wire

TABLE 3.1 Comparison of Three Package Stacking Technologies: PoP, PiP, and FSCSP