Page 159 -

P. 159

4.4 Fabrication 149

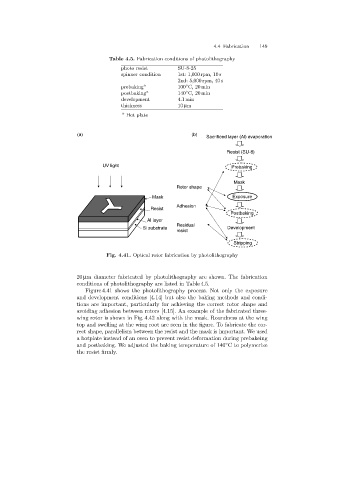

Table 4.5. Fabrication conditions of photolithography

photo resist SU-8-25

spinner condition 1st: 1,000 rpm, 10 s

2nd: 5,000 rpm, 40 s

prebaking a 100 C, 20 min

◦

◦

postbaking a 140 C, 20 min

development 4.1 min

thickness 10 µm

a

Hot plate

(a) (b)

Sacrificed layer (Al) evaporation

Resist (SU-8)

UV light Prebaking

Mask

Rotor shape

Mask Exposure

Adhesion

Resist

Postbaking

Al layer

Residual

Si substrate Development

resist

Stripping

Fig. 4.41. Optical rotor fabrication by photolithography

20 µm diameter fabricated by photolithography are shown. The fabrication

conditions of photolithography are listed in Table 4.5.

Figure 4.41 shows the photolithography process. Not only the exposure

and development conditions [4.14] but also the bakingmethods and condi-

tions are important, particularly for achievingthe correct rotor shape and

avoidingadhesion between rotors [4.15]. An example of the fabricated three-

wingrotor is shown in Fig. 4.42 alongwith the mask. Roundness at the wing

top and swellingat the wingroot are seen in the figure. To fabricate the cor-

rect shape, parallelism between the resist and the mask is important. We used

a hotplate instead of an oven to prevent resist deformation duringprebakeing

and postbaking. We adjusted the baking temperature of 140 C to polymerize

◦

the resist firmly.