Page 161 -

P. 161

4.4 Fabrication 151

2. a Si-based negative resist with high resistance to oxygen reactive ion-beam

etching(O 2 RIE) is spin-coated onto the polyimide layer and exposed to

an electron beam

3. the polyimide layer is etched down to the Si substrate by O 2 RIE

4. after removal of the resist, the microrotor are freed from the substrate by

ultrasonic vibration.

Fluorinated polyimide has a density of 1.49 and a refractive index of 1.53 at

a wavelength of 1.064 µm as listed in Table 3.3.

4.4.2 Microphotoforming

In order to increase the optical torque of the rotor, it is effective to adopt a 3-D

structure with slopes on its upper surface. To fabricate such 3-D microstruc-

tures, photoformingis applied. However, the presently proposed photoforming

apparatus is large and requires a special laser beam (ultra-short-pulsed near-

infrared Ti:sapphire)or special resin (two-photon-absorbed urethane material)

[1.29, 4.17].

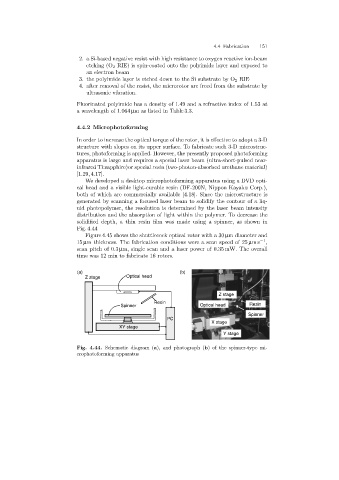

We developed a desktop microphotoformingapparatus usinga DVD opti-

cal head and a visible light-curable resin (DF-200N, Nippon Kayaku Corp.),

both of which are commercially available [4.18]. Since the microstructure is

generated by scanning a focused laser beam to solidify the contour of a liq-

uid photopolymer, the resolution is determined by the laser beam intensity

distribution and the absorption of light within the polymer. To decrease the

solidified depth, a thin resin film was made usinga spinner, as shown in

Fig. 4.44

Figure 4.45 shows the shuttlecock optical rotor with a 30 µm diameter and

15 µm thickness. The fabrication conditions were a scan speed of 25 µms −1 ,

scan pitch of 0.3 µm, single scan and a laser power of 0.35 mW. The overall

time was 12 min to fabricate 16 rotors.

(a) (b)

Z stage Optical head

Z stage

Resin

Spinner Optical head Resin

Spinner

PC

X stage

XY stage

Y stage

Fig. 4.44. Schematic diagram (a), and photograph (b)of the spinner-type mi-

crophotoforming apparatus