Page 324 - A Practical Guide from Design Planning to Manufacturing

P. 324

294 Chapter Nine

B

A

No mask required

Poly

O

O

O

O

iO

S S S S Si S S S S Si S S S S Si iO 2 2 2 2 2 2 2 2 2

iO

O

O

O

O

O

O

O

O

O

O

O

O

O

S S SiiO 2

P-well N-well

Deposit Si N

3 4

O

O

O

O

O

O

O

O

O

O

S S S S SiiO S S S S Si S S S S Si iO

O

S S S S SiiO

iO

iO

O

O

S S S S Si S S S S Si

iO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

N N 2 2 2 2 2 2 2 2 2 2 P P N N 2 2 2 2 2 2 2 2 2 2 P P

P-well N-well P-well N-well

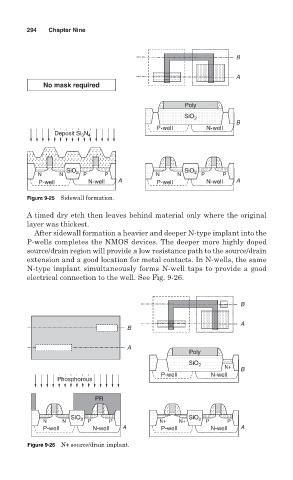

Figure 9-25 Sidewall formation.

A timed dry etch then leaves behind material only where the original

layer was thickest.

After sidewall formation a heavier and deeper N-type implant into the

P-wells completes the NMOS devices. The deeper more highly doped

source/drain region will provide a low resistance path to the source/drain

extension and a good location for metal contacts. In N-wells, the same

N-type implant simultaneously forms N-well taps to provide a good

electrical connection to the well. See Fig. 9-26.

B

A

B

A

Poly

O

O

O

O

O

iO

iO

O

O

O

O

O

O

O

O

O

O

O

O

S S S S Si S S S S Si S S S S Si iO

S S SiiO

2 2 2 2 2 2 2 2 2 2

N+

P-well N-well

Phosphorous

PR

O

O

O

O

O

O

O

O

O

O

O

O

O

iO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

iO

iO

O

O

S S S S SiiOO S S S S SiiO

O

O

iO

O

O

O

S S S S Si S S S S Si

S S S S Si S S S S Si

N N 2 2 2 2 2 2 2 2 2 2 P P N+ N+ 2 2 2 2 2 2 2 2 2 2 P P

P-well N-well P-well N-well

Figure 9-26 N+ source/drain implant.