Page 325 - A Practical Guide from Design Planning to Manufacturing

P. 325

Semiconductor Manufacturing 295

B

A

B

A

Poly

O

O

O

O

O

iO

S S S S Si S S S S Si S S S S Si iO 2 2 2 2 2 2 2 2 2

O

iO

O

O

O

O

O

O

O

O

O

O

O

S S SiiO 2

P+ N+

P-well N-well

Boron

PR

O

O

O

O

O

iO

S S S S Si S S S S Si

iO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

S S S S SiiOO

S S S S Si S S S S Si iO S S S S SiiO

O

O

iO

N+ N+ 2 2 2 2 2 2 2 2 2 2 P P N+ N+ 2 2 2 2 2 2 2 2 2 2 P+ P+

P-well N-well P-well N-well

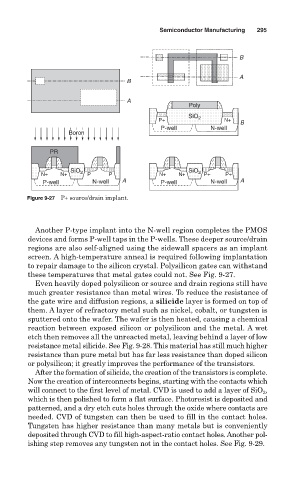

Figure 9-27 P+ source/drain implant.

Another P-type implant into the N-well region completes the PMOS

devices and forms P-well taps in the P-wells. These deeper source/drain

regions are also self-aligned using the sidewall spacers as an implant

screen. A high-temperature anneal is required following implantation

to repair damage to the silicon crystal. Polysilicon gates can withstand

these temperatures that metal gates could not. See Fig. 9-27.

Even heavily doped polysilicon or source and drain regions still have

much greater resistance than metal wires. To reduce the resistance of

the gate wire and diffusion regions, a silicide layer is formed on top of

them. A layer of refractory metal such as nickel, cobalt, or tungsten is

sputtered onto the wafer. The wafer is then heated, causing a chemical

reaction between exposed silicon or polysilicon and the metal. A wet

etch then removes all the unreacted metal, leaving behind a layer of low

resistance metal silicide. See Fig. 9-28. This material has still much higher

resistance than pure metal but has far less resistance than doped silicon

or polysilicon; it greatly improves the performance of the transistors.

After the formation of silicide, the creation of the transistors is complete.

Now the creation of interconnects begins, starting with the contacts which

,

will connect to the first level of metal. CVD is used to add a layer of SiO 2

which is then polished to form a flat surface. Photoresist is deposited and

patterned, and a dry etch cuts holes through the oxide where contacts are

needed. CVD of tungsten can then be used to fill in the contact holes.

Tungsten has higher resistance than many metals but is conveniently

deposited through CVD to fill high-aspect-ratio contact holes. Another pol-

ishing step removes any tungsten not in the contact holes. See Fig. 9-29.