Page 326 - A Practical Guide from Design Planning to Manufacturing

P. 326

296 Chapter Nine

B

A

No mask required

Silicide

Silicide Silicide

Poly

O

O

O

O

iO

S S S S Si S S S S Si S S S S Si iO 2 2 2 2 2 2 2 2 2

O

iO

O

O

O

O

O

O

O

O

O

O

O

O

S S SiiO 2

P+ N+

P-well N-well

D eposit re f ractory meta l

Deposit refractory metal

Silicide Silicide

O

O

O

O

O

O

O

O

O

O

iO

S S S S SiiO

iO

O

O

O

O

iO

S S S S Si S S S S Si

S S S S SiiO S S S S Si S S S S Si iO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

N+ N+ 2 2 2 2 2 2 2 2 2 2 P+ P+ N+ N+ 2 2 2 2 2 2 2 2 2 2 P+ P+

P-well N-well P-well N-well

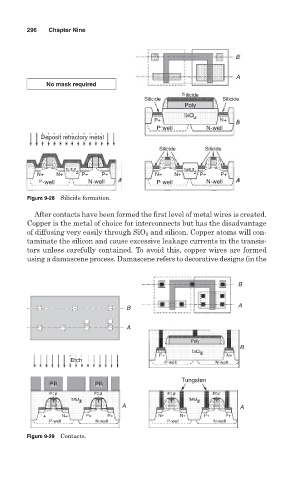

Figure 9-28 Silicide formation.

After contacts have been formed the first level of metal wires is created.

Copper is the metal of choice for interconnects but has the disadvantage

of diffusing very easily through SiO 2 and silicon. Copper atoms will con-

taminate the silicon and cause excessive leakage currents in the transis-

tors unless carefully contained. To avoid this, copper wires are formed

using a damascene process. Damascene refers to decorative designs (in the

B

B A

A

Poly

B

O

O

O

O

O

O

O

O

O

O

S S S S SiO

S S S S Si S S S S Si O 2 2 2 2 2 2 2 2 2 2 2

O

O

O

O

O

O

P+ N+

Etch P-well N-well

Tungsten

PR PR

o

o

P P Poooly

o

P P P

o

P P P Po o oly l l l y y y y y y y y y y P P P P P Pooly l l l y y y y y y y y y y P P P P P Poooly l l l y y y y y y y y y y P P P P P P P P P Poolly ly l l y y y y y y y y y y

o

o

o

oly

o

ol

o

P P P Po

o

P P P Po

o

oly

o

o

o

O

O

O

O

O

O

O

O

O

O

O

O

O

O

S S S S Si S S S S Si

S S S S Si S S S S Si

S S S S SiiO 2 2 2 2 2 2 2 2 2 2 2 S S S S SiiOO 2 2 2 2 2 2 2 2 2 2 2

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

iO

iO

iO

iO

A A

N+ N+ P+ P+ N+ N+ P+ P+

P-well N-well P-well N-well

Figure 9-29 Contacts.