Page 164 - Semiconductor Manufacturing Handbook

P. 164

Geng(SMH)_CH12.qxd 04/04/2005 19:49 Page 12.13

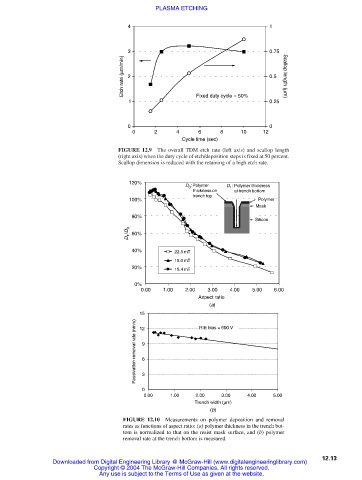

PLASMA ETCHING

4 1

3

Etch rate (µm/min) 2 0.5

0.75 Scallop length (µm)

1 Fixed duty cycle = 50% 0.25

0 0

0 2 4 6 8 10 12

Cycle time (sec)

FIGURE 12.9 The overall TDM etch rate (left axis) and scallop length

(right axis) when the duty cycle of etch/deposition steps is fixed at 50 percent.

Scallop dimension is reduced with the retaining of a high etch rate.

120%

D : Polymer D : Polymer thickness

0

1

thickness on at trench bottom

trench top

100% Polymer

Mask

80%

Silicon

D 1 /D 0 60%

40% 22.5 mT

18.0 mT

20% 15.4 mT

0%

0.00 1.00 2.00 3.00 4.00 5.00 6.00

Aspect ratio

(a)

15 RIE bias = 500 V

Passivation removal rate (nm/s) 9 6

12

0 3

0.00 1.00 2.00 3.00 4.00 5.00

Trench width (µm)

(b)

FIGURE 12.10 Measurements on polymer deposition and removal

rates as functions of aspect ratio: (a) polymer thickness in the trench bot-

tom is normalized to that on the resist mask surface, and (b) polymer

removal rate at the trench bottom is measured.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) 12.13

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.