Page 189 - Semiconductor Manufacturing Handbook

P. 189

Geng(SMH)_CH13.qxd 04/04/2005 19:51 Page 13.12

PHYSICAL VAPOR DEPOSITION

13.12 WAFER PROCESSING

characterization are x-ray diffraction (XRD), electron dispersive x-ray spectroscopy/wavelength

dispersive x-ray spectroscopy (EDX/WDX), Auger electron spectroscopy (AES), scanning electron

microscope (SEM), and transmission electron microscope (TEM). XRD is used to determine the

crystallinity and texture of the layers. A broader peak signifies smaller grain size. EDX/WDX is used

to determine the composition of the layers, to detect contamination, stoichiometry of compound layers

and reaction of donors, and dopant materials with underlying base layers.

Zones 1–3 as in evaporation

Zone T—fiber-type closely packed layer with smooth surface

13.7 SPUTTER EQUIPMENT

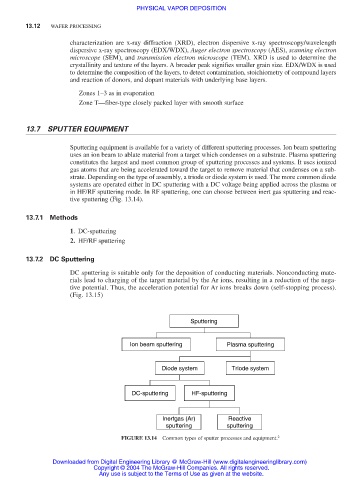

Sputtering equipment is available for a variety of different sputtering processes. Ion beam sputtering

uses an ion beam to ablate material from a target which condenses on a substrate. Plasma sputtering

constitutes the largest and most common group of sputtering processes and systems. It uses ionized

gas atoms that are being accelerated toward the target to remove material that condenses on a sub-

strate. Depending on the type of assembly, a triode or diode system is used. The more common diode

systems are operated either in DC sputtering with a DC voltage being applied across the plasma or

in HF/RF sputtering mode. In RF sputtering, one can choose between inert gas sputtering and reac-

tive sputtering (Fig. 13.14).

13.7.1 Methods

1. DC-sputtering

2. HF/RF sputtering

13.7.2 DC Sputtering

DC sputtering is suitable only for the deposition of conducting materials. Nonconducting mate-

rials lead to charging of the target material by the Ar ions, resulting in a reduction of the nega-

tive potential. Thus, the acceleration potential for Ar ions breaks down (self-stopping process).

(Fig. 13.15)

Sputtering

Ion beam sputtering Plasma sputtering

Diode system Triode system

DC-sputtering HF-sputtering

Inertgas (Ar) Reactive

sputtering sputtering

FIGURE 13.14 Common types of sputter processes and equipment. 2

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.