Page 173 - Separation process principles 2

P. 173

138 Chapter 4 Single Equilibrium Stages and Flash Calculations

procedure is repeated until the compositions xjl) and xj2), to Results for isopropanol and acetone are in reasonably good agree-

say three or four significant digits, no longer change from ment at these relatively dilute conditions, considering that no

one iteration to the next. Multicomponent liquid-liquid temperature corrections were made.

equilibrium calculations are best carried out with a steady-

state simulation computer program.

4.7 SOLID-LIQUID SYSTEMS

EXAMPLE 4.8 Solid-liquid separation operations include leaching, crystal-

lization, and adsorption. In a leaching operation (solid-

An azeotropic mixture of isopropanol, acetone, and water is being liquid extraction), a multicomponent solid mixture is sepa-

dehydrated with ethyl acetate in a distillation system of two

rated by contacting the solid with a solvent that selectively

columns. Benzene was previously used as the dehydrating agent,

dissolves some, but not all, components in the solid. Al-

but recent legislation has made the use of benzene undesirable

though this operation is quite similar to liquid-liquid extrac-

because it is carcinogenic. Ethyl acetate is far less toxic. The over-

tion, two aspects of leaching make it a much more difficult

head vapor from the first column, with the composition given

below, at a pressure of 20 psia and a temperature of 80°C is con- separation operation in practice. Diffusion in solids is very

densed and cooled to 35"C, without significant pressure drop, caus- slow compared to diffusion in liquids, thus making it diffi-

ing the formation of two liquid phases in equilibrium. Estimate the cult to achieve equilibrium. Also, it is virtually impossible to

amounts of the two phases in kilograms per hour and the phase completely separate a solid phase from a liquid phase. A

compositions in weight percent. clear liquid phase can be obtained, but the solids will be

accompanied by some liquid. In comparison, the separation

Component kgh of two liquid phases is fairly easy to accomplish.

Isopropanol 4,250 A second solid-liquid system involves the crystallization

Acetone 850 of one or more, but not all, components from a liquid mix-

Water 2,300 ture. This operation is analogous to distillation. However,

Ethyl acetate 43,700

although equilibrium can be achieved, a sharp phase separa-

tion is again virtually impossible.

Note that the specification of this problem satisfies the degrees of

A third application of solid-liquid systems, adsorption,

freedom from (4-4), which for C = 4 is 9.

involves the use of a porous solid agent, which does not un-

dergo phase change or composition change. The solid selec-

SOLUTION tively adsorbs, on its exterior and interior surface, certain

components of the liquid mixture. The adsorbed species are

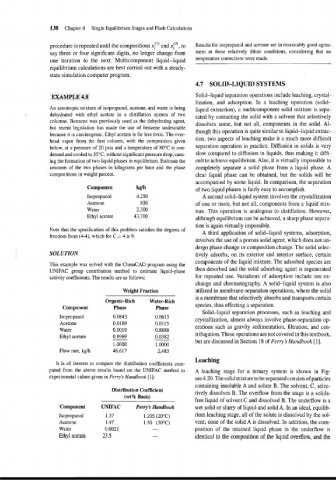

This example was solved with the ChemCAD program using the

then desorbed and the solid adsorbing agent is regenerated

UNIFAC group contribution method to estimate liquid-phase

activity coefficients. The results are as follows: for repeated use. Variations of adsorption include ion ex-

change and chromatography. A solid-liquid system is also

Weight Fraction utilized in membrane-separation operations, where the solid

is a membrane that selectively absorbs and transports certain

Organic-Rich Water-Rich

species, thus effecting a separation.

Component Phase Phase

Solid-liquid separation processes, such as leaching and

Isopropanol 0.0843 0.0615 crystallization, almost always involve phase-separation op-

Acetone 0.0169 0.01 15

erations such as gravity sedimentation, filtration, and cen-

Water 0.0019 0.8888

Ethyl acetate 0.8969 0.0382 trifugation. These operations are not covered in this textbook,

but are discussed in Section 18 of PerryS Handbook [I].

1 .oooo 1 .oooo

Flow rate, kgh 48,617 2,483

Leaching

It is of interest to compare the distribution coefficients com-

puted from the above results based on the UNIFAC method to A leaching stage for a ternary system is shown in Fig-

experimental values given in Perry's Handbook [I]:

ure 4.20. The solid mixture to be separated consists of particles

containing insoluble A and solute B. The solvent, C, selec-

Distribution Coefficient tively dissolves B. The overflow from the stage is a solids-

(wt % Basis)

free liquid of solvent C and dissolved B. The underflow is a

Component UNIFAC Peny 's Handbook wet solid or sluny of liquid and solid A. In an ideal, equilib-

Isopropanol 1.37 1.205 (20°C) rium leaching stage, all of the solute is dissolved by the sol-

Acetone 1.47 1.50 (30°C) vent; none of the solid A is dissolved. In addition, the com-

Water 0.0021 - position of the retained liquid phase in the underflow is

Ethyl acetate 23.5 - identical to the composition of the liquid overflow, and the