Page 211 - The Geological Interpretation of Well Logs

P. 211

- IMAGE LOGS -

N E s Ww N DIP—>

m = wn W o 30 180 270 360 «=O* 60°

|

dipping bed ~~

dip azimuth

=low point

: ™~ tangent = dip angle D>

a ~--> oo

horizontal bed

A. Borehole B. Image - ‘unwrapped’ borehole C. Dipmeter

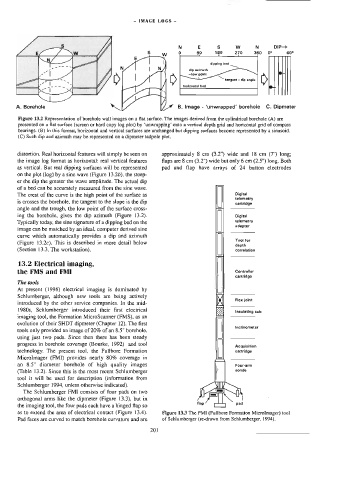

Figure 13.2 Representation of borehole wall images on a flat surface. The images derived from the cylindrical borehole (A) are

presented on a flat surface (screen or hard copy log plot) by ‘unwrapping’ onto a vertical depth grid and horizontal grid of compass

bearings. (B) In this format, horizontal and vertical surfaces are vachanged but dipping surfaces become represented by a sinusoid.

(C) Such dip and azimuth may be represented on a dipmeter tadpole plot.

distortion. Real horizontal features will simply be seen on approximately 8 cm (3.2”) wide and 18 cm (7") long;

the image log format as horizontal: real vertical features flaps are 8 cm (3.2") wide but only 6 cm (2.5") long. Both

as vertical. But real dipping surfaces will be represented pad and flap have arrays of 24 button electrodes

on the plot (log) by a sine wave (Figure 13.25), the steep-

er the dip the greater the wave amplitude. The actual dip

of a bed can be accurately measured from the sine wave.

The crest of the curve is the high point of the surface as Digital

telametry

is crosses the borehole, the tangent to the slope is the dip

cartridge

angle and the trough, the low point of the surface cross-

ing the borehole, gives the dip azimuth (Figure 13.2). Digital

Typically today, the sine signature of a dipping bed on the telemetry

adapter

image can be matched by an ideal, computer derived sine

curve which automatically provides a dip and azimuth

Tool for

(Figure 13.2c). This is described in more detail below

depth

(Section 13.3, The workstation). correlation

Me

13.2 Electrical imaging,

cartridge

the FMS and FMI Controller

The tools

At present (1996) electrical imaging is dominated by

Schlumberger, although new tools are being actively

Flex joint

introduced by the other service companies. In the mid-

1980s, Schiumberger introduced their first electrical

trsulating sub

imaging tool, the Formation MicroScanner (FMS), as an

Microlmager (FMI) provides nearly 80% coverage in inclinometer

evolution of their SHDT dipmeter (Chapter 12). The first

tools only provided an image of 20% of an 8.5” borehole,

using just two pads. Since then there has been steady

progress in borehole coverage (Bourke, 1992) and tool

Acquisition

technology. The present tool, the Fulfbore Formation

“an 8.5" diameter borehole of high quality images cartridge

Four-arm

(Table 13.2). Since this is the most recent Schlumberger sonde

tool it will be used for description (information from

Schlumberger 1994, unless otherwise indicated).

The Schlumberger FMI consists of four pads on two

=

orthogonal arms like the dipmeter (Figure 13.3), but in

flap [ 1 pad

the imaging tool, the four pads each have a hinged flap so

as to extend the area of electrical contact (Figure 13.4). Figure 13.3 The FMI (Fullbore Formation Microlmager) too)

Pad faces are curved to match borehole curvature and are of Schlumberger (re-drawn from Schlumberger, 1994).

201